'Tis the season for young skiers to make threads on this website bemoaning the wild mount jobs shops inflicted on their precious sticks. So here's a followup on the topic of Swiss cheese skis.

Last year I wrote about my frustration with the prevalence of mis-mounted skis. Many of the negative responses to that article came from folks defending ski techs, arguing that I was being too hard on under-payed, overworked folks who make up the core of our local ski scenes. But that was never my intent. Rather, ski techs who screw up mounts are simply the final piece in a larger puzzle of failure. When you see that tech standing over your skis, holding the drill guiltily and muttering “oh fuck” under their breath, they’re simply the most visible step in an antiquated process that’s riddled with potential for failure. Mismounted skis are usually a systemic issue, and we need systemic solutions.

And to be clear. If you, or the shop you’re associated with, screwed up a mount or two last year and did your best to make things right with the customer, I’m not trying to call you out. Mistakes will happen, even inside of good accountability systems. NASA lost a $125 million probe because they overlooked standard/metric unit conversions, nobody is expecting you to be perfect. But right now, the state of the industry is far from perfect.

The Customer’s Job

Before we get into the bigger picture systemic stuff, it’s always worth harping on what you, the customer, can do to make sure you don’t become the victim of a missmount. This isn’t any sort of guarantee that you’ll get your skis back without any extra holes in them, but it’s a good place to start. If you take these steps as a customer, you can unequivocally say it’s 100% the shop’s fault if something goes wrong.

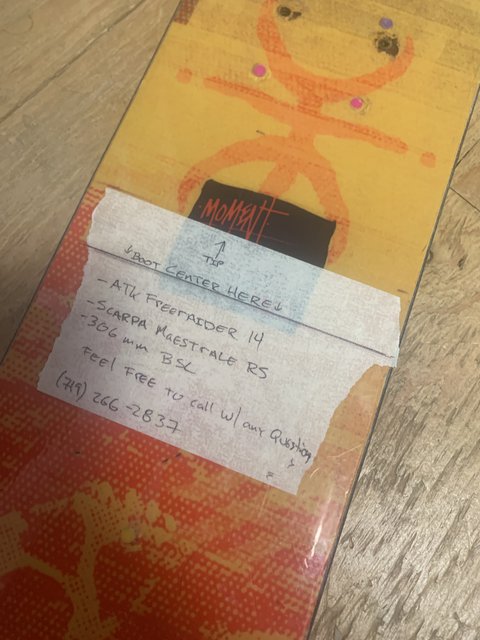

Put a piece of painter’s tape on each of the two skis in the pair. On each piece of tape write down the following info:

-The binding this skis is being drilled for (if it’s a frame binding, note if it’s the “small” or “large” version of that binding)

-The boot model that they’re being drilled for

-The BSL of that boot (it’s stamped into the plastic of the boot somewhere near the sole)

-An arrow pointed toward the tip of the ski

-A line where you want the midsole of your boot to fall on the ski

-Your phone number

Yes, that’s a bit of work, but it takes just a moment to do, and gives whatever tech ends up mounting your ski all the info they need.

It’s important to remember that often the person that you talk to about getting your skis mounted is not the same person who will drill holes in them. So telling them any details verbally, without writing them down, is just playing telephone with important information.

Beyond the tape with all the details, I also like to mark the centerline of my boot with a silver paint marker. I draw the center line where I want my skis mounted with the same paint marker. That makes things very simple.

As a customer, it’s important to remember that the ski shop is a business, with deadlines, so just because you can trade a six pack for a mount with your buddy, doesn’t mean you should plan on not paying and still getting great service. The same goes for timing. Don’t expect an immediate turnaround. Give them time to do a good job.

A note about centers

A complicating aspect is that “center” means different things in different contexts when it comes to skis. Terms like “true center”, “sidecut center”, and “chord center” all get thrown around, and it’s even less helpful when we say things like “centered on recommended” or talk about mount points in terms of +/- cm from an arbitrary point.

And on top of all that, some manufacturers really suck at putting their center marks in a consistent place. I’ve reviewed skis that had the “recommended” lines printed 2.5 cm further forward on one ski than the other.

My personal solution, that I think is the easiest to employ, is for you, as the customer, to take a few things into your own hands.

First: Always measure your own mount points. It’s pretty easy to find the actual center of your skis. Lay them down, take a measuring tape, measure them, divide that number in half, mark the center. You don’t even need a metric measuring tape, and you can even ask Siri to do all your math and then convert to centimeters.

Once you know where the actual center of the ski is, check the manufacturer’s recommended mount point. Even if they have center punched the ski’s sidewall, go to their website, look up the ski, and the mount point they recommend for your length. If it’s not on the site, they probably have a chatbot function that can help you.

If you want to mount at that recommended line (which you probably should, but I understand why you wouldn’t) draw a line across the topsheet at that point. If you want to mount forward or back from that line, add or subtract centimeters before you draw your line.

The biggest takeaway is to double check where you actually want the center of your boot to fall on the ski, before you take it in to be drilled. Be kind to your tech, don’t be a dick, but also make it hard for them to screw up your mount.

Systems

All that said, it shouldn’t be possible for it to be the “customer’s fault” when a mount goes wrong. Most shops need to implement better systems to make sure the tech knows exactly what the customer wants done. When a customer drops off skis, the paperwork they fill out should be comprehensive. It should include the ski model, length, boot model, and boot sole length. It should also include the mount point, as well as that mount point’s distance from “true center” the mathematical middle of the ski. If the customer doesn’t know that, then it should specify which line already printed on the ski the binding is being mounted at. A copy of this paperwork should be taped to the ski, and the customer should go home with another.

I know, I know, your shop already requires that paperwork right? I’ve been to plenty of shops that have those forms covered. And plenty of those same shops also don’t check to make sure you’ve filled them out fully, and don’t give you a receipt so you have proof of what you asked for. Plenty of shops have those forms and don’t consistently use them, instead relying on word of mouth as the customer drops a pile of gear on the counter. I wish we could do things that way, but the pile of threads about messed up mounts on this site and others proves the current system doesn’t work.

Beyond the paperwork, the industry needs to take steps to make it harder for techs to screw up. A good start would be to pay experienced ski techs more. Most ski shop employees are underpaid in money in favour of non-tangible remuneration in things that feed their passion. Getting paid too little to work in a ski shop kills that passion and you end up with burnt out misanthropes poking holes in skis. As I said in my piece last year:

“Not everybody is blasé about new skis like you are, oh burnt-out tech. Not everyone has access to pro deals and demos and is constantly surrounded by the latest and greatest. Plenty of folks have one pair of skis that means a whole lot to them, that they sacrificed to get, and that carries a lot of memories. And you get to take a drill and put holes in it wherever your careless ass pleases. Make it count. Skis are special, don’t ruin them before they even get used.”

So let’s take steps to make techs less burnt out. Pay them more. Incentivize them working with precision and doing good mounts. Make sure they are armed with good information about where the customer wants the mount to happen. Encourage them to call the customer if there’s anything that seems outlandish on that check-in sheet.

Cost vs. Value

Ski mounts are usually not cheap. Tanner Hall’s recent insta posts reflecting shock at being charged $75 for a mount were a good reminder. New skis cost somewhere in the ballpark of $700, and when we pay roughly 10% of that price again, to get holes drilled in them, I think it’s fair to expect precision. And if that $75 mount is in the wrong place, or for the wrong binding, those skis are suddenly worth closer to $450 than the $700 you paid for them. It’s common practice for shops to offer a free remount and tune if they mess up your mount. That’s not really a fair restitution though. Even with that wax and grind that they probably don’t really need, your new skis are suddenly worth a lot less than when you bought them, and you haven’t even gotten to ski through any ditches on them yet.

All that said, if we trusted ski shops to do a better job with mounts than they currently do, $50 or $60 for a mount wouldn’t be outrageous. The problem is that right now there’s too high a chance of getting a mis-mount that actively depreciates your skis.

Accountability

In my last piece I suggested that shops should have a clearly stated replacement policy for mis-mounted skis, and that there should be repercussions for techs who routinely mess up mounts. Some folks were not stoked on that. But I’ll stand my ground. If we built robust systems of accountability to do everything reasonable in our power to ensure well mounted skis, there would be fewer remounts, and having real repercussions for those mistakes wouldn’t tank a shop or tech.

If a ski shop mis-mounts your brand new skis, they should replace them. Period. If they’re some exotic hard to find model that were custom made for you, too bad, they owe you a new pair. That sucks, it’s frustrating for the shop, but it should be written into their margins on mounts.

If the shop messes up a mount on a previously mounted pair of skis and it’s clearly their fault (the customer gave them all the correct info as detailed above) they should work with the customer to make it right. That doesn’t necessarily mean replacing their beat up, core shot, edge cracked old skis with a brand new pair, but it does mean hooking them up with services or products that are roughly equivalent to the depreciation they caused on those skis.

If you’ve got a tech who’s constantly miss-mounting skis, even when handed all the pertinent information, they should maybe not be allowed to drill holes in skis at your shop anymore. This shouldn’t be controversial. Do what you can to make sure that it’s hard for accidents to happen, and then, when they do, do everything in your power to fix them.

There are a lot of pressures on local shops right now as online retail eats up more and more of the market, and big box chains encroach on what’s left. Mounting skis is one of the few things you don’t need to compete with the .com’s for. It’s one of the few things that you’re set up to do significantly better than generic outdoor stores. But for some reason, so many small local shops drop the ball on mounts. And if you can’t even put the right holes in the right place on our skis, why should we buy anything from you when it’s cheaper online? We all want local shops to thrive, and a good way to be leaders in their space would be to guarantee great mounts. Too many don’t. To the ones that do, thank you!

Why it all matters

So much of the magic of skiing is present in the tiny details. Only a few degrees of angle distinguish a zeach from a proper grind. We shovel urban stairs and accept that tiny changes in posture have a big affect on a skier’s overall style. We know how wide our skis are to the millimeter, we obsess over wax choice based on temperature and conditions. We are dorks. And in the big picture, none of that really matters. We’re sliding down frozen water on overly-fancy planks.

But that’s no excuse to drill the wrong holes in the wrong places in those planks. If anything, it’s an exhortation to be more careful and precise with that process. None of this really matters, so you might as well take pride in the little things.

Comments