In December 2019, at the end of my third day on a brand new pair of skis, I returned home to find that the sidewall was fully shattered underfoot (image below). I hadn't had any landings that felt like they were onto rocks, but I had a decent-sized core shot directly underfoot, so I probably did. I immediately emailed Armada customer support, who, after a few weeks, told me that this was not covered under their warranty. So, I found a $100 pair of skis on Craigslist and finished the season on those. But this fall, I tried to fix the ski, and after putting a few days on my finished product, I think I was successful. I'm writing up the process I used so that if others find themselves in a similar situation, they might have something to refer to.

I began the repairs by cross-drilling through the cracked ABS, and about 2" into the ski, then using a utility knife to cut the ABS off. Note that I drilled the holes about an inch past the end of the cracked ABS. Once I had the ABS off, I cleaned out all of the fractured wood splinters.

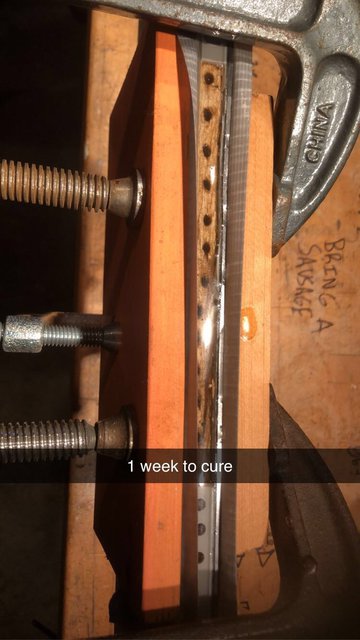

I had already bought a product called Git-Rot, which is a marine epoxy that is designed to match the elasticity of wood, and is used to repair rotting wooden boats. Since Armada Declivity X is a wood core ski, this seemed like a good choice to keep the flex of the damaged ski comparable with that of the undamaged one. Git-Rot wicks into wood, and the more porous the wood is, the more Git-Rot can soak in. Since the edge of the ski was bent out of shape, I used two clamps and two pieces of flat scrap wood to flatten the metal out as much as possible. Then, I poured Git-Rot into the holes that I had cross-drilled until it was level with the surface of the ABS that was still there. Since Git-Rot will continue to soak into the wood, I stayed and watched it for about 20 minutes. whenever the surface level of the fluid started to dip down below the ABS, I poured more in. In the image below, note the duct tape clamped between the ski and the wood. This is necessary to prevent the wood from being epoxied to the ski. While it's not visible, the duct tape fully covers the core shot on the base of the ski, which would have had epoxy coming out of it and bonding to the board along the base.

Git-Rot is intended to cure overnight at 70 degrees F, but since this was in an unheated garage in December, I left it to cure for a full week before continuing with the process. The two images below show what the ski looked like after curing. You can see the while the edge is not back to being as straight as it was originally, it has somewhat improved. Since this ski is 115mm underfoot, and I don't really plan on skiing it on hard pack much, if ever, I don't think this is a big deal.

With the Git-Rot fully cured, the damaged ski still wasn't as stiff as the undamaged one, which makes sense, due to the missing piece of ABS underfoot. I'm fortunate enough to have a mechanical engineer for a father, who works at a company with a full machine shop, so he took the ski in to work and used a CNC machine to route route out the section of Git-Rot, and lowered the material down by the thickness of a piece of ABS. I realize many people don't have access to this, so readers will have to figure out their own process for this next part. Many colleges have machine shops, so take advantage of that if you're in a position to do so.

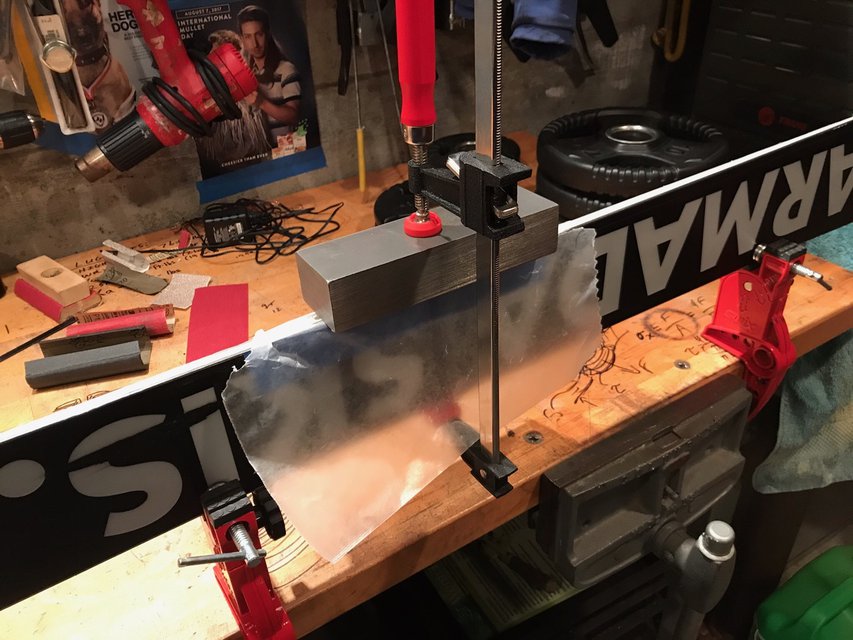

Once the material had been lowered, I used Devcon DP125, an epoxy used to bond wood and ABS products, to stick a single layer of abs into the opening that had been created for it. I clamped this down, and left it for 24 hours to cure.

After a few hand-flexes, it was clear that this ski was still not as stiff as the undamaged one. So I glued on another layer of ABS. This layer does stick out from the rest of the ski, but I was able to sand down the edges so there are no corners.

This made the skis close enough in flex for me to mount them and go ski them in the resort. After one resort day, I decided that they seemed like they wouldn't break on me. But since I don't really want to go through this process again, I am making them a dedicated touring ski, since I generally am not as hard on my equipment while touring.

If you've made it this far, I hope that you found this process useful. Sometimes ski manufacturers make skis in fun shapes but with crappy construction. With this process, you may be able to avoid paying way too much money for a new pair of skis when your new ones just broke.

Comments