Production is the time of the year when you wait on your materials from all around the world to arrive. For us that arrival destination is Reno, Nevada, where we make all of our skis. It's also a time to wish that it would start snowing again because you constantly look at next year's product every day.

So far this year we have made the Comi, Ruby 180/188/190, M1 182/192, and Tahoe 180/188. All the skis this year have new and improved materials. We have a new core with Pine in addition to our super light Aspen. The Pine is a better wood for screw bite thus reducing pullouts. It also has a lot of other great properties that make the skis more fun and lively. We also have two new topsheet materials this year, some with different textures and finishes to change how the graphic looks and to reduce chipping.

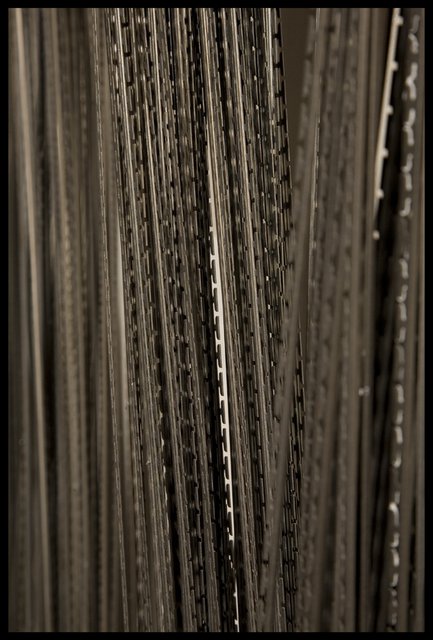

After testing new edges all winter we have came up with the best edges yet. The 2.5mm thick edges are Rockwell hardened to 48 and also annealed by us in the locations where it matters. This means, longer lasting edges on rails.

Along with all the fun of making the same skis over and over all summer we also get to play around with new designs. Several new skis are already being made for testing in New Zealand and Whistler.

That about sums it up here at the factory…check back soon for more updates.

New website up by the end of the month!

Comments